HAVS – What is it and how do I deal with it?

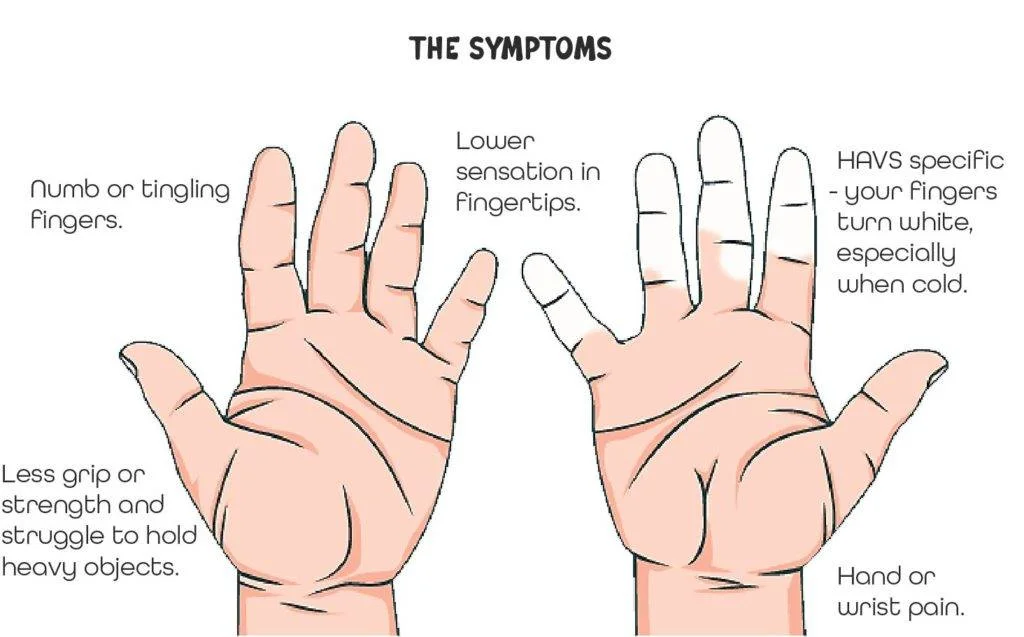

Vibration issues are no new topic in detailing. Dual-action polishers have been massively beneficial to results and efficiency since overtaking rotary polishers in popularity, however vibration has become a serious concern, as HAVS (Hand Arm Vibration Syndrome) – or another similar issue known as “Raynaud’s syndrome” – can cause a range of issues from tingling and numbness to almost frostbite-like damage when used excessively. Charachterised as White finger, due to it affecting the blood flow to fingertips when related to hand tools, the issues are not just a muscular result, but can lead to skeletal and neurological disorders. With pressure to complete and process work as quickly as possible some detailers, especially those starting up, are far exceeding recommended work times on machines and other issues such as poor technique or basic setup are exacerbating the issue. However, higher end manufacturers are getting better at reducing the impacts through better design, cushioning materials and bushed connections. and the effects can be minimised with a few simple steps and some common sense. But what are we trying to prevent?

Is it affected by tool quality?

Lower quality machines – not just polishers, but drills, sanders, every power tool that has a powered moving part – will usually cause more aggressive vibration compared to higher quality items, because these small improvements which dampen down the effects cost money to develop and implement – often requiring specialised tooling, more expensive materials and more design steps, etc – all of which would add to the price of a cheap tool. Expense doesn’t completely eliminate the issue though, as there is always a level of vibration – even mildly in rotary polishers. Sometimes it’s not directly linked to the machine, but the attachments. An off centre backing plate, or pad for instance can multiply minimal vibrations by multiple factors.

Power tool manufacturers have always looked for ways to make inherently vibrating machines less damaging – not only for health reasons but productivity – a relaxed and comfortable tool is going to give better results! Sadly, the less you pay for a tool, the less investment is made in user comfort, so a higher quality, well serviced tool is going to deliver you better health as well as it’s other qualities.

Other side-effects

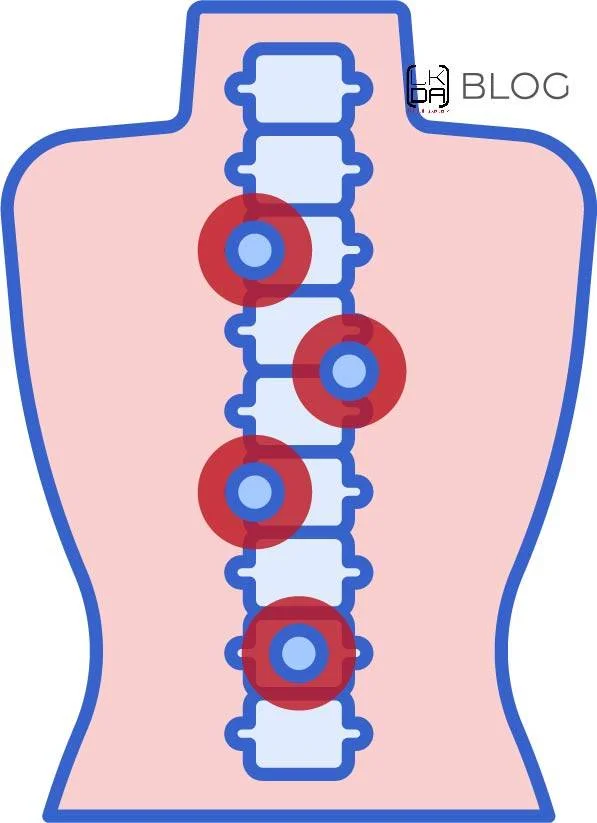

Sitting down when using DA polishers can also transfer these forces down your spine and into your pelvis, resulting in lower back issues – if you’re relying on your spine to support you whilst working – rather than your legs which can cushion low vibrations, your spine becomes a grounding rod for the vibration “energy”, so where possible work standing or kneeling comfortably instead of perching on a stool.

Tips for lowering vibration effects:

Centre pads correctly – the most common reason for excessive vibration in a higher quality machine is incorrectly placed pads throwing off the balance.

Try a switch to thinner pads – less mass = less eccentric throw energy.

Check the machines periodically for loose components and have them serviced anually.

Take regular breaks to stretch out and rest arms and hands.

Alternate between vibrating and low-vibration tools, such as rotary polishers.

Keep hands warm and dry when using vibrating machines – colder hands = slower blood flow, keep em warm and you’ll fatigue slower.

Wear anti vibration gloves, and if standing for long periods stand on a secure soft surface such as a large kneeling mat or piece of carpet.

If you experience any prolonged numbness, show symptoms of low blood circulation in extremeties or ongoing pain from machine use, consult your doctor as it’s a health issue which will only get worse, and could end up career ending…

PPE and personal safety is a core module within all our detailing career courses, and serves to get you working safely from the start so that you can enjoy a long and productive career. Check out our start-up courses such as Level One if you’re looking to come into the industry, of for an overview of how you can make your business more safe for you and your clients, have a look at our Health and Safety for business course to see where you can make tweaks and improvements.